Two Component Liquid Optical Silicone Gel Sealant SI8506

$0.00

Two Component Liquid Optical Silicone Gel Sealant SI8506

∎Product Description

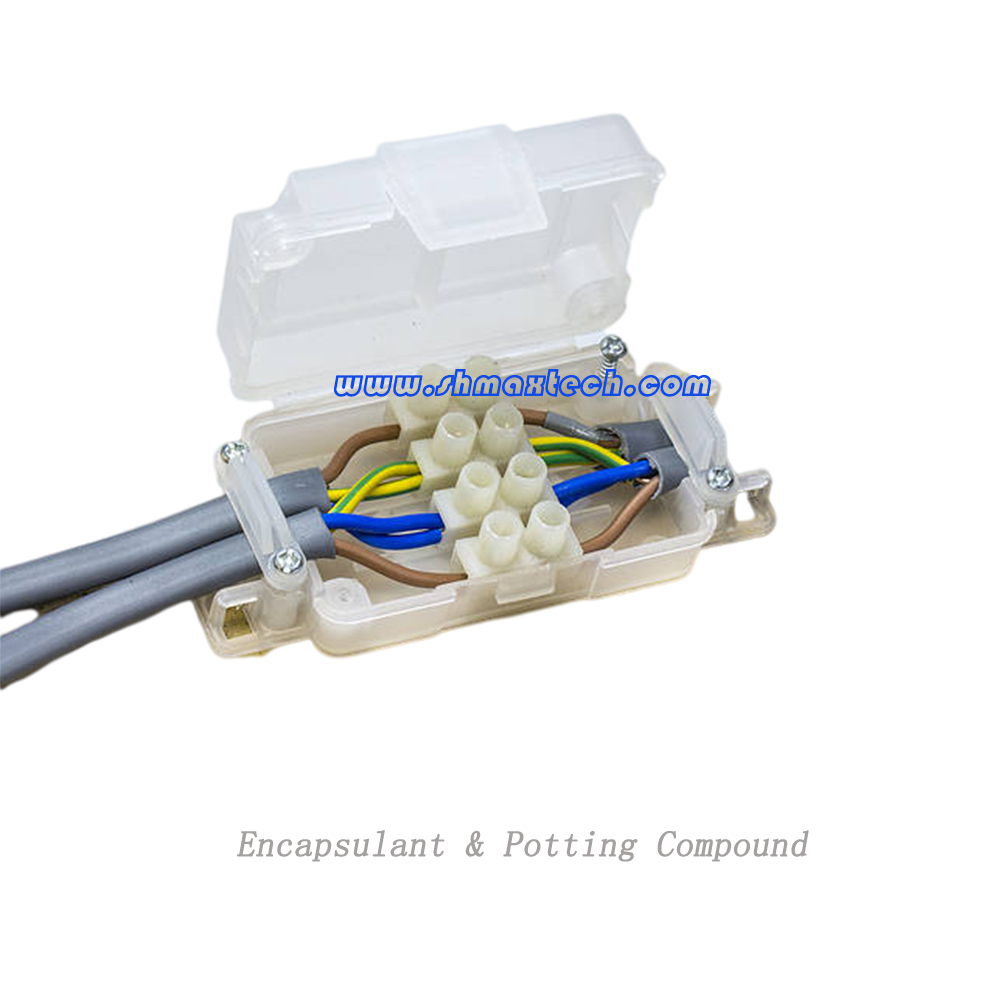

SI8506 Silicone liquid optical sealant is a two-component optical grade transparent material that can be fitted with a variety of LCD display module window materials, including glass, PMMA acrylic and PC polycarbonate, with excellent optical properties such as high transparency, low atomization, lowest yellowness and excellent reliability. It can help the LCD display module to work for a long time under various working conditions.

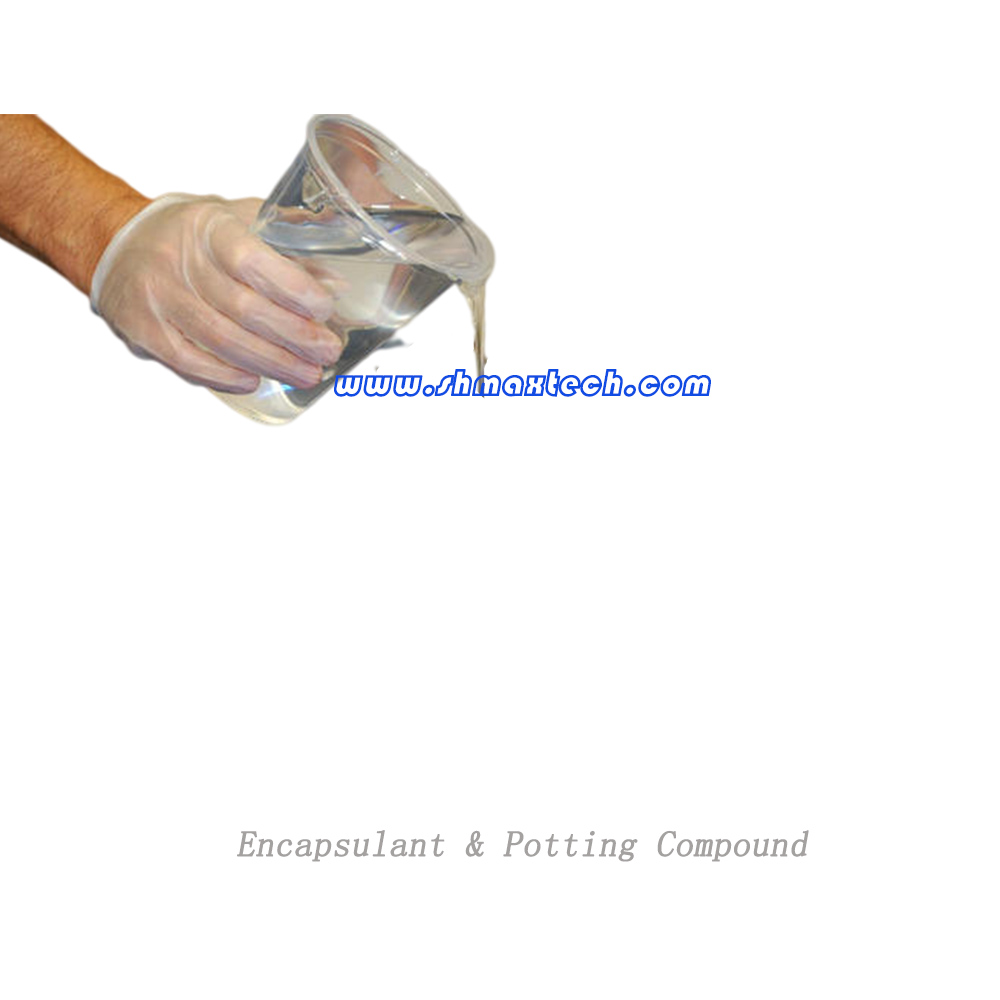

SI8506 silicone liquid optical sealant can be cured at room temperature or at medium temperature heating. It maintains a high transparency before and after curing. No byproducts are released during curing. Low shrinkage makes it suitable for large-size display modules. After curing, it is very soft and has high surface viscosity, The colloidal toughness is easy to repair.

∎Typical Applications

-

-

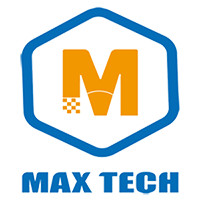

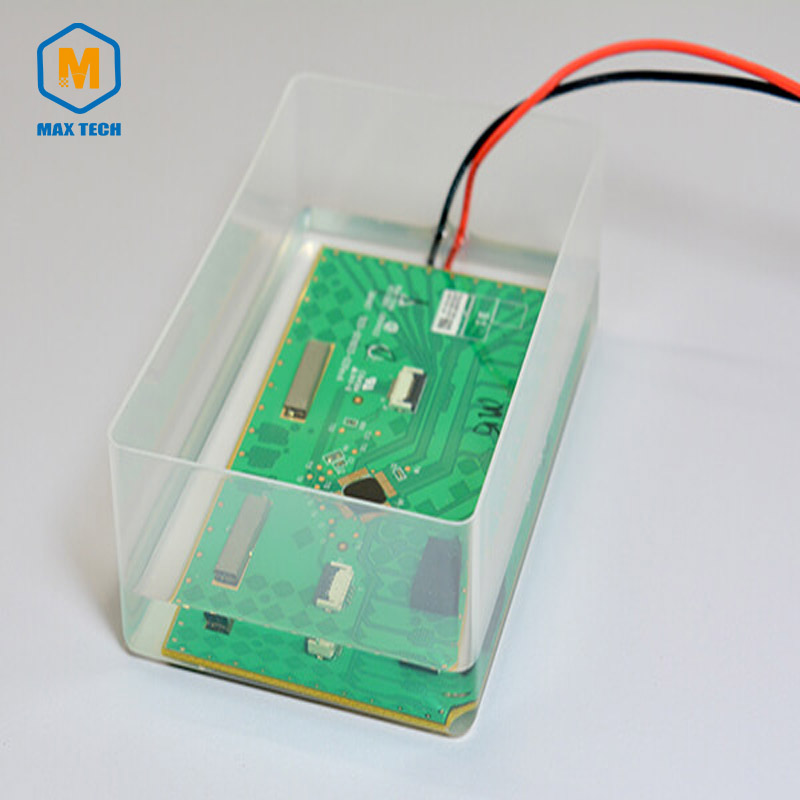

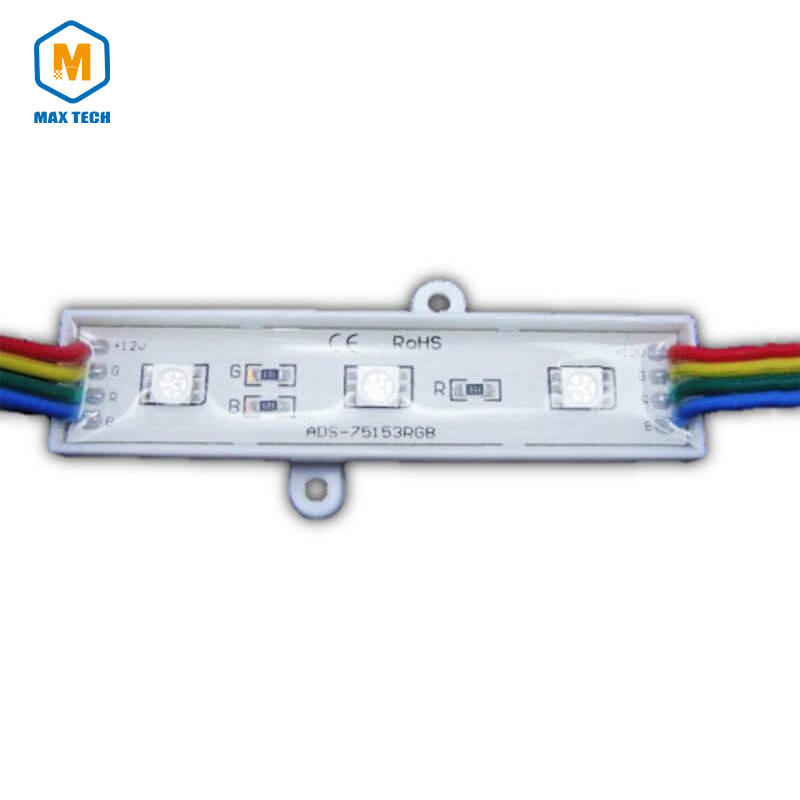

- Used for optical fit with the LCD/OLED display screen with the window cover

- For installationof optical grade sensors

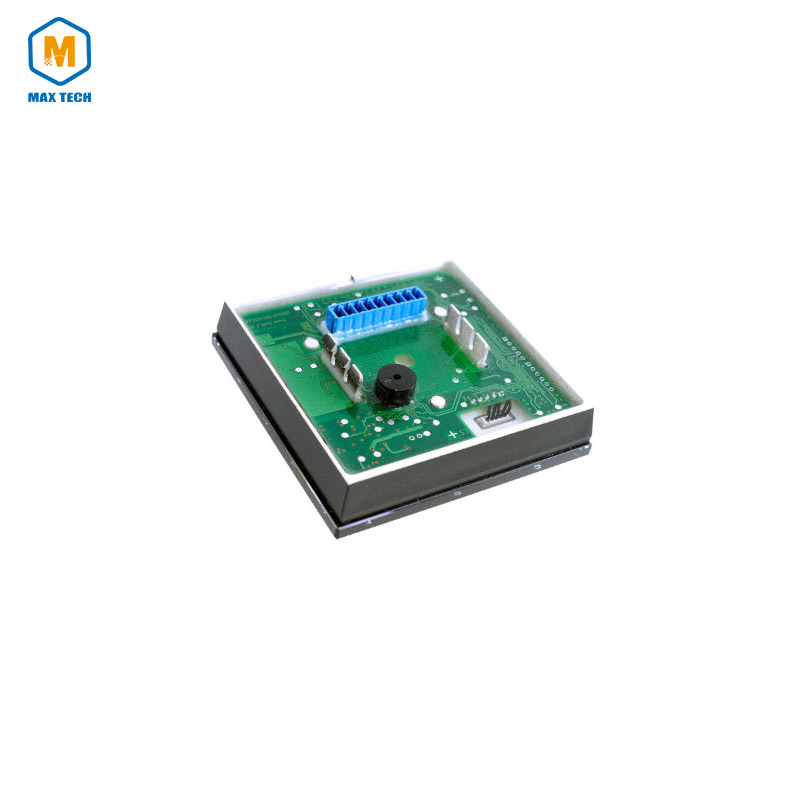

- For Semiconductor IGBT and thyristor module

- Widely used in Automotive electronic module

-

Description

Two Component Liquid Optical Silicone Gel Sealant SI8506

∎Product Description

SI8506 Silicone liquid optical sealant is a two-component optical grade transparent material that can be fitted with a variety of LCD display module window materials, including glass, PMMA acrylic and PC polycarbonate, with excellent optical properties such as high transparency, low atomization, lowest yellowness and excellent reliability. It can help the LCD display module to work for a long time under various working conditions.

SI8506 silicone liquid optical sealant can be cured at room temperature or at medium temperature heating. It maintains a high transparency before and after curing. No byproducts are released during curing. Low shrinkage makes it suitable for large-size display modules. After curing, it is very soft and has high surface viscosity, The colloidal toughness is easy to repair.

∎Typical Applications

-

-

- Used for optical fit with the LCD/OLED display screen with the window cover

- For installationof optical grade sensors

- For Semiconductor IGBT and thyristor module

- Widely used in Automotive electronic module

-

∎Technical Data Table

| PROPERTY | STANDARD/UNITS | VALUE of SI8506 Clear | |

| —- | —- | PART A | PART B |

| Material | —- | Polysiloxane | 100% Solid Content |

| Color | Visual inspection | Colorless Liquid | Colorless Liquid |

| Viscosity | 25°C, cps | 700 | 650 |

| Density | 25°C, g/cm3 | 0.98 | 0.98 |

| Mixture/mass ratio | —- | A:B=100:100 | |

| Viscosity of mixture | 25°C, cps | 700 | |

| Operation time | 25°C, min | 30mins | |

| Gel time | 60°C, min | 10mins | |

| Initial curing time | 60°C, min | 16mins | |

| Post curing time | 25°C, hr | 24hr | |

| Elogation at break | 100% | >400% | |

| Refractive Index | 25°C | 1.41 | |

| Transmittance | % | 450nm, 1mm, >99 | |

| Transmittance | % | 800nm, 1mm >99 | |

| Haze | – | <0.1% | |

| Yellowing Index | – | <0.2% | |

| Thermal Conductivity | W/m.K | 0.22 | |

| Hardness | 1/10mm | 50 | |

| Breakdown Voltage | KV/mm | 25 | |

| Volume resistance | DC500V, ohm-cm | 2.0×1015 | |

| Loss factor | 1 MHz | 0.009 | |

| Dielectric constant | 1 MHz | 2.9 | |

| Application temperature | °C | -60~260 | |

Note:All above data were tested under standardized condition, or tested by further experiments.

∎Key Features

-

- 1:1 addition type,Mixing convenience

- High Transmittance

- Low yellow change

- Room temperature curing or heating curing

- High toughness and surface viscosity

- More optimized processability

∎Packing Specification

-

- Part A—10 KG/Bucket

- Part B—10 KG/ Bucket.

∎Transport &Storage

-

When stored at or below 35°C in the original unopened containers, this product has a usable life of 12 months from the date of production.

-

Sampling test is necessary for products which exceed shelf life before taking use. During storage may have little settlement stratification, stirring evenly when use, does not affect performance.

It’s non-dangerous goods, can be transported as normal chemicals, CAUTION leakage during transport.

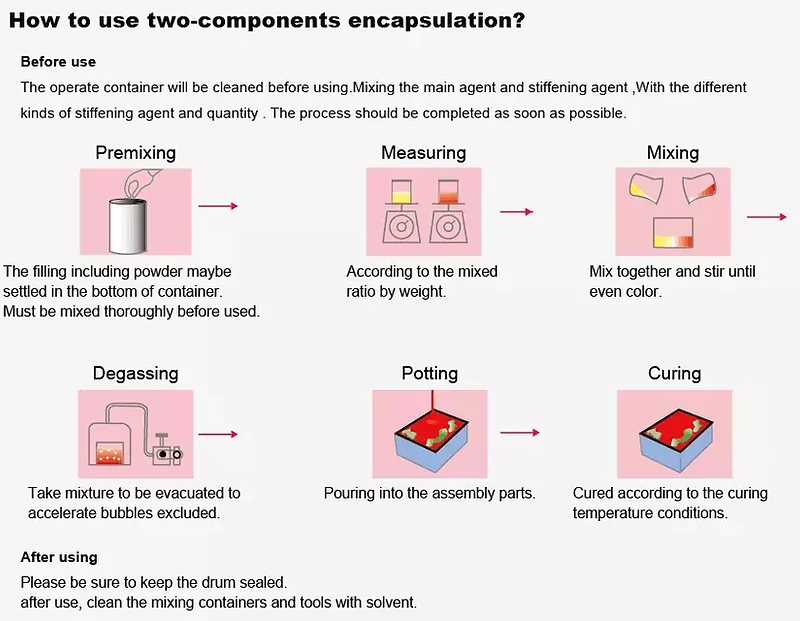

∎Directions for Use

-

-

-

- Mix the A and B components at a ratio of 1: 1

- mixed

Take a clean plastic container and add AB components to the mixing container in a predetermined proportion for rapid mixing. Bubbles will be introduced into the colloid during the mixing process. For mass production, it is recommended to use automatic mixing equipment (static mixing mode is recommended) with automatic glue filling

3) Defoaming

If the hand-mixed require debubbling , it is recommended to remove the bubbles under the vacuum of 10mmHg immediately after mixing for 5-10 minutes, the specific time is referred to the mixed amount. The volume of the glue should not exceed 1/3 of the container volume during off-bubbles to avoid overflowing.

4) Pointing tools

Use a syringe after defoaming

Please contact our market department for irrigation or quantitative glue.

5) Operation process

Relieving the temperature will shorten the operation time, please pay attention!

Similarly, in winter, the lower temperature will significantly reduce and solidify.

6) Plastic fit: After mixing 8506, apply glue with slitting or ordering fish bone diagram

In the dam, flipping with the LCD atmosphere;

7) Heating and curing: Send the fitted products together with the fixture into the oven

60C*20min heating and solidification to ensure the flatness of the placement;.

Heating will accelerate the curing of gel, and the temperature can be appropriately increased by the temperature;

-

-

∎Attention of operation

-

Keep away from Children

-

Avoid contact with eyes and skin. If contact with your skin, scrub first with soap wateror alcohol, then rinse with water. If contact with your eyes, rinse with plenty of water, andseek medical treatment immediately.

-

It is forbidden to build on the surface of the wet substrate.

∎Safety Operation Data

MSDS isn’t included here. Please read TDS, MSDS and label carefully before operation. You can get MSDS from MAXTECH or other distributors, or mail to service center maxtech@shmaxtech.com

∎Warranty and Liability

All product properties and application details based on information believe to be reliable and accurate. But you still need to test its property and safety before application. The advice we supply don’t apply in any circumstances. MAXTECH don’t make assurance of any other applications outside the specification until MAXTECH supply a special written guarantee. MAXTECH is only responsible to replace or refund if this product is defective within the warranty period stated above. MAXTECH makes it clear that will not be liable of any accidents.

∎FAQ

-

Q : How long can I get a quote?

A: The quotation can be provided no longer than 24hours on condition that we know all detailed requirement.

Q: Do you accept private Label?

A: Yes. ODM & OEM are welcome

Q:Can We get a samle before order?

A: Of course. Generally, we provide 1-5 pieces free samples for quality testing and the courier fee be born by customers. Thanks for your understanding.

Q:Do you have MOQ ?

A: Yes, Generally ,MOQ is1000-2000kg

Q: How long will finished my order?A: It’s depend on your order quantity. Generally, we just need around 10 days to produce 5000kg after receive your

payment.

Q: How to find the suitable sealant ?A: Please let me know your application purpose,substrate, application method and all your requirements. We would like give you a recommendation.

Reviews

There are no reviews yet.